Tomato grower continues testing upgrade tomato harvest robot with new variety

inaho and Kwekerij Duijvestijn continue their collaboration in 2025, testing the upgraded tomato harvesting tobot with Harmoniz Seed’s variety Dormaplum. The upcoming season will focus on further field testing of inaho’s autonomous tomato harvesting robot, which now features a fully redesigned structure and upgraded capabilities.

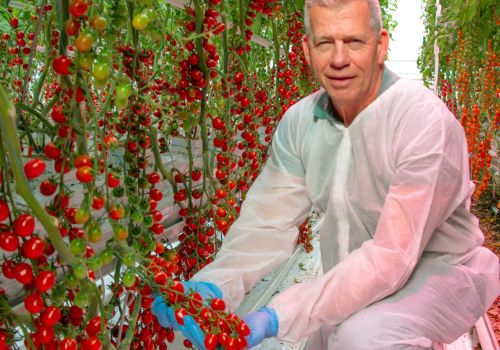

In 2024, inaho conducted a successful trial of its harvesting robot at Kwekerij Duijvestijn using Dormaplum, a snack tomato variety developed by Harmoniz Seed. The characteristics of Dormaplum – particularly its compact trusses, low sensitivity to fruit damage, and strong shelf life – proved to be highly compatible with robotic harvesting, contributing significantly to the robot’s enhanced performance during the trial.

“The compact cluster formation and strong shelf life of Dormaplum allowed the robot to perform with significantly higher efficiency,” says Yu Mizuki, Director of inaho Europe. “It retained more ripened fruits per truss for longer periods, which directly contributed to the increase in harvesting performance.”

Building on this positive outcome, inaho will conduct a new round of trials in 2025 using its completely redesigned harvesting robot. The robot includes major performance upgrades, shares Mizuki. He points at industrial-grade reducers, motors, sensors, and cameras for superior speed, durability, and picking precision, a smooth, curved frame design to prevent snagging and reduce the risk of damaging plants or structures. Also a dual-camera system is mounted on both sides of each crop lane, drastically improving fruit recognition time and the harvesting belt is optimized, developed in collaboration with partners and tailored specifically for snack tomato harvesting. “These innovations bring inaho closer to commercial-scale deployment, offering a dependable solution for specialty tomato growers.”

inaho’s harvesting robot is designed under the concept of “No Investment & reduce 40%+ of your labor cost,” offering a practical, low-risk solution for growers facing labor shortages and cost pressures.

Varieties more compatible with automation

Encouraged by the performance of Dormaplum in robotic harvesting trials, inaho and Harmoniz Seed are exploring the development of tomato varieties that are more compatible with automation. As labor availability continues to decline and labor costs continue to rise, breeding efforts are expected to increasingly focus on labor-friendly traits.

“We see great promise in aligning breeding strategies with automation technologies. With Dormaplum we enhance the flavour, and fruit quality when we harvest full red colour while the fruit keep their excellent shelf life ” says Wilfred Scheffers, Europe Sales Manager at Harmoniz Seed. “The Dormaplum trial was a strong indication of what’s possible when variety characteristics and robotic design work in harmony.”

Those interested in inaho’s tomato harvesting robot can contact a company representative to learn more about its features and gain insights from field trials conducted in the Netherlands. In addition, Harmoniz Seed opened its new demonstration center, PROOF, last year, where visitors can observe the Dormaplum variety in cultivation.